Fully Automated

Fully automated solution is used for set technologies and automatic control devices that results in the automatic operation and control of processes without significant human intervention. This helps achieve superior performance than manual control. These automation devices include PLCs, PCs, PACs, conveyors, trolleys, etc. and technologies include various industrial communication systems.

Handling Solutions

Automated material handling systems ensure efficient transport of material from one place to another in the manufacturing area – within the same department or bay, on opposite ends of the manufacturing floor, or even in two separate buildings.

Robotic De-burring Solutions

Deburring is the process of removing burrs, edges, inconsistencies or fins off of parts. Robotic deburring is when this process is carried out by industrial robotic arms. Robotic deburring provides numerous benefits over manual deburring, and these benefits are getting harder to ignore.

Welding Solutions

Robotic welding automates the welding process to increase accuracy, enhance safety and reduce the time needed to complete each project. These benefits make the robotic welding process a popular alternative to manual metal joining. Several industries take advantage of this automated process to get the results they need as quickly as possible.

Robotic Washing Machine

Looking for ways to increase process efficiency and productivity? Automating the parts washing process is a great way to implement simple, but significant improvements. If you have considered the idea of automated parts washing but thought it would be complicated or cost-prohibitive, now is the time to revisit the idea! SSA can do custom engineered solutions and has several highly flexible approaches to automating the parts washing process to realize significant cost savings and efficiency gains.

Parts Tracker for Assembly

With increased automation comes a rising need for more automated ways to identify the parts and materials in production. SSAs AMR expanding to meet the demand in new environments.

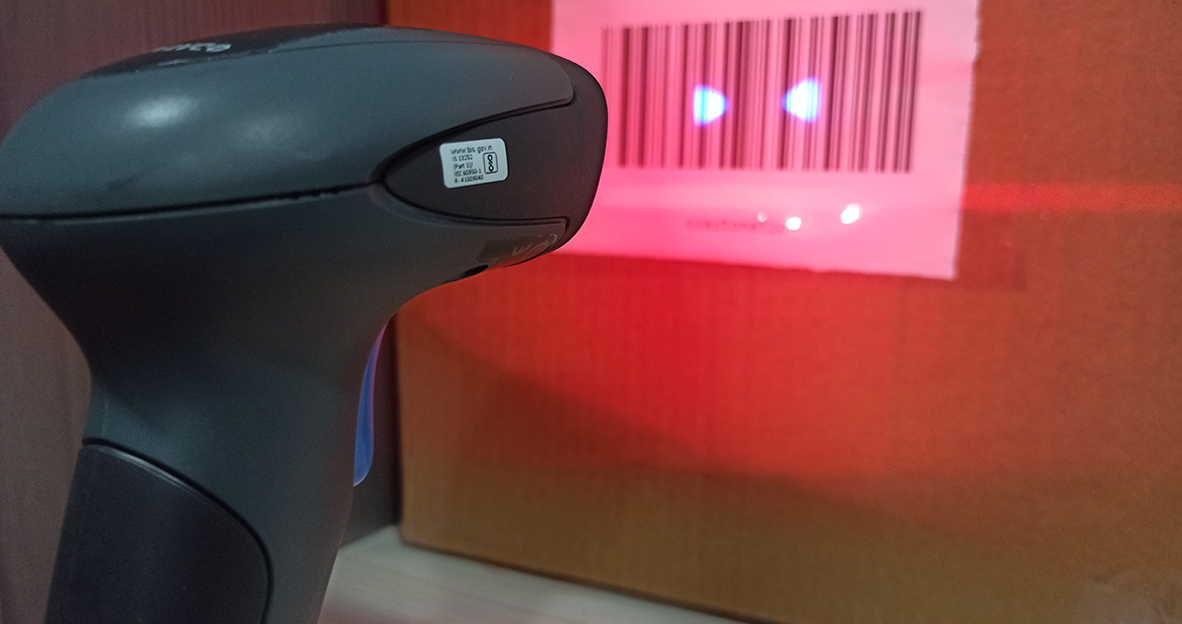

Bar Code & QR Readers & Integration

SSAs barcode scanner and integration is capable of reading 2D or 3D Barcode or QR code on stable or moving boxes over conveyor with any orientation of Barcode/ QR code label.

Aerospace

SSAs Machine vision, robotics, and manufacturing intelligence are enabling the aerospace industry to automate tasks that pose safety risks for employees, are tedious, or time consuming – increasing production capacity and improving quality. From fabrication to assembly to inspection, there are many processes within the aerospace industry that have high potential for automation and many of these are already being automated. Below are a few examples of solutions that SSA will provide.

Simple Warehouse Management for Sub Assembly Parts

SSAs AMR can navigate the warehouse to bring goods to workers. It saves time and reduces miles of walking by employees. It works alongside a human staff member, picking up shelves of goods and transporting them to a work station to pick and sort.

Transmission & Distribution

Transmission and distribution refers to the different stages of carrying electricity over poles and wires from generators to a home or a business. Below shown solution is provided by SSA for coating the wires.

Get in touch

CLOSE

CLOSE